Assembly Capacity

Assembly Capacity

There are 4 SMT patch production lines equipped with new imported Samsung high speed SMT machine,fully automatic paste printing machine,ten temperature zone return furnace,AOI, SPI, x-ray and other high-end equipment.Especially good at high precision, high complexity of the board

|

Component size

|

03015--55*100MM

|

|

BGA gap

|

0.2MM

|

|

IC gap

|

0.18MM

|

|

Double-sided board、Assemble circuit board、Test board、DIP、Flexible printed circuit board、Soft and hard combined board

|

|

SMT speed

|

0.1S

|

|

Component specification

|

SMT precision

|

±0.05MM

|

|

XRAY

|

YES

|

|

Laser steel mesh

|

420*520MM 550*650MM 736*736MM

|

|

PCB specification

|

PCB Size

|

50*50MM-610*510MM

|

|

PCB Thickness

|

0.3-6.5MM

|

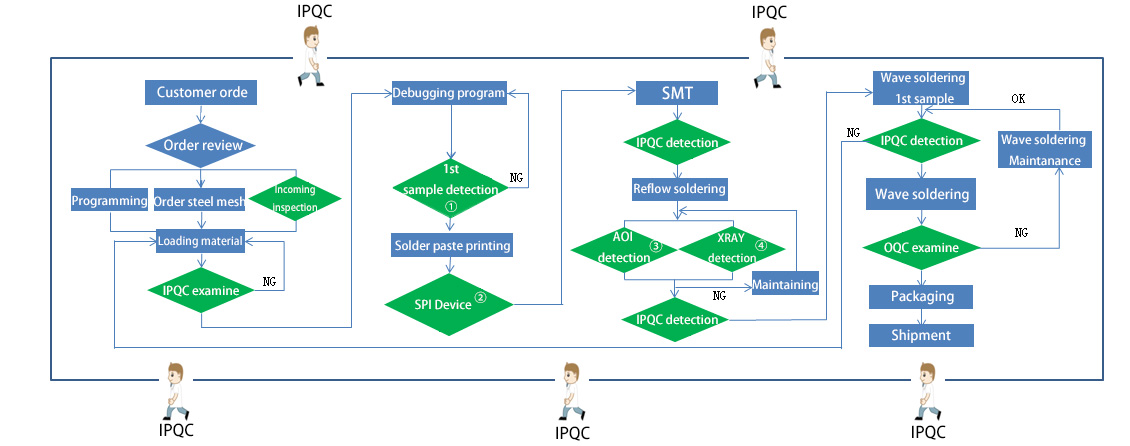

SMT Process Flow

SMT Process Flow

High-quality

High-quality

Production line is equipped with high-end equipment, high precision and high yield processing.Quality inspection and control at each link to avoid defective products flowing into the next link

| 1. 1st sample detection |

Detection of wrong materials, missing parts, polarity, direction, screen printing, etc., mainly used in the detection of the first part,compared with manual detection, the accuracy is higher |

| 2. SPI Device |

Detect all kinds of solder paste printing quality problems |

| 3. AOI |

Detect all kinds of problems after installation: short connection, missing material, polarity, shift, wrong parts |

| 4. Xray |

Open circuit and short circuit detection of BGA, QFN and other devices |

Processing Equipment